|

EZ Status Indication Lights

Displays the status of remote or inaccessible

sensors

Compact units replace cumbersome post or stack

lights

Available in 2 to 5 colours

Available in straight, right-angle and dome-shaped

housings

Eliminates bulb replacement with long-lasting LEDs

Compatible with PLC or other logic-level control

outputs

|

|

|

Ford Motor works

in Cologne used over 400 different sensors from various

manufacturers. Ford additionally maintained extensive inventories of

standard devices and non-official stocks in drawers and shelves.

Ford settled for 6 different Uprox+ sensors to replace all the

sensor variants used. |

New Factor 1 Inductive

Sensors

"Everything that can be invented, has

been invented". So said Charles Duell, Director of the U.S.

Patent Office in 1899! One might think the same about the inductive

proximity sensor. It has remained virtually the same since it's

invention over a century ago.

With a complete

departure from the traditional ferrite core, the new Uprox+ Sensors

offer many advantages over the old design. One of the primary

advantages is the achievement of Factor 1 sensing i.e. the ability

to sense all metals equally. Ferrite core sensors are rated by their

ability to sense a mild steel target but suffer huge loss of

sensitivity when detecting other metals.

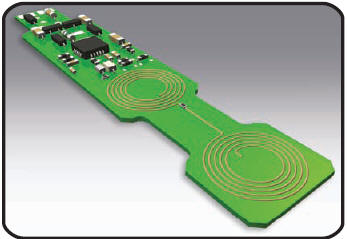

A newly patented

multicoil system for the Uprox+ product line replaces the

conventional wound coil system used in the previous generation of

sensors. This results in extraordinary sensing distances (up to 250

percent higher than conventional ferrite core inductive sensors) in

a Factor 1 sensor. Due to the unique design, they give the

flexibility to incorporate this technology in several new housings

that solve a number of unique customer applications. All Uprox+

sensors have an environmental rating of IP 68 are weld-field immune,

provide an extended temperature range and offer highest levels of

EMC.

The ability to

lay the coils flat results in a totally new sensor which can replace

a ring sensor and is far simpler to install or replace.

Click

HERE for more on Inductive Sensor Facts

|

|

Multibarriers

for Foundation Fieldbus & Profibus PA

With Foundation Fieldbus and

Profibus-PA fieldbus systems, many applications require Zone 1 installation. The

use of Multibarriers

allows the

use of a bus segment for the explosion hazardous area with the same segment

structures as in the non intrinsically-safe area , without the danger of

potential transfers. The supply of energy to the physical layer is implemented

in the non-explosion hazardous area – in the control room. The segment cable is

subject to the regulations governing enhanced safety (Exe). Junction boxes

(multibarriers) can now be connected to this bus cable, which subdivide the Exe

cable into 4 Exi trunk lines. As a result, it is possible to supply energy for

segments designed for longer distances. |

|

|

New Fieldbus Displays

These bus powered instruments,

which can display up to eight fieldbus process variables on a 86 x 45mm screen,

are available for use with Fieldbus Foundation or Profibus PA systems. One, two

or four fieldbus variables may be displayed at the same time, together with

units of measurement and tag information. The operator can select the displayed

screen via the front panel push-buttons, or these buttons may be disabled.

By writing to the transducer

block parameters, text and simple graphics can also be displayed. The

push-buttons can then be used to return operator acknowledgements: if large

industrial push-buttons are required for these operator inputs, external

push-buttons or switches may be wired to the instrument. The two intrinsically

safe models, which have ATEX, FM and IEC Ex certification, comply with the

Fieldbus Intrinsically Safe Concept FISCO.

|