|

| |

Vision Sensors

"Smart" Inspection

Cameras

|

Why Vision

Sensors?

Repetitive inspection of production lines is a labour-intensive

activity that is being replaced by vision sensors which are not only

cost-effective, but give consistency of judgement and documented

traceability to the inspection process.

How do they

work?

Vision sensors have huge numbers of photoelectric cells that capture

a complete image. The amount of detail (the resolution), expressed

as the pixel count depends on how many photoelectric cells the

sensor contains (e.g. 1.3 million pixels). After capturing the image, the

vision sensor compares some, or a number of characteristics of the image to the reference image stored in its memory.

So, if the sensor is set to recognize a blister pack with eight undamaged

tablets, it knows to reject a pack that has only seven tables or a broken

tablet. Also the packet can be anywhere within the camera’s field of view. And

it can inspect asymmetrical objects no matter how they are rotated within a full

360o range. They have a wide variety of production applications.

Which characteristics the sensor compares to the reference image is

set using software

inspection

tools built into the sensor. Some sensors have all the

available software tools built-in and some simpler sensors have only

the tool they need to do a particular task, saving cost and

simplifying both set-up and operation. |

|

| The sequence

begins when sensor is triggered to take an image. The sensor has

been programmed to enable it locate, analyse and measure the image

and then compare the results with preset pass or fail criteria. The

result is communicated over Ethernet or RS232 coms ports. The

Tools

which enable the sensor locate, analyse, measure and decide are

important features for the effectiveness and simplicity of the

system. For many applications, a simple "Teach" facility is a huge

benefit. |

Trigger Sensor |

|

Vision Sensors

can often be selected more easily from known applications where the

various parts have been specified.

See Below.

Please

contact us if you wish to ask for further advice or a

product demonstration.

You may prefer to see the full

Sensor Range

The following application examples are

provided to assist in seeing the potential for vision sensors in any

manufacturing environment.

|

|

APPLICATIONS: |

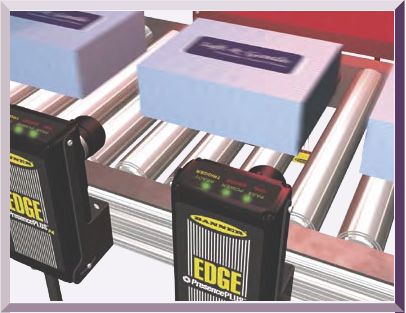

Label Alignment

Objective: To

verify that the labels on a bottle are aligned with each other and

both are straight.

Sensors: Presence PLUS P4 EDGE, with

LCF08 lens,

HFFW12DC

tubular fluorescent light, PLC used as a trigger.

Operation: Two labels are glued to the front of a bottle –

one on the neck and another on the body. The

Presence PLUS P4

EDGE’s

Locate tool finds the edge of the bottle, and then the two Edge

tools verify that the top and bottom labels are lined up and not

skewed. |

Complete Assembly Inspection

Objective: To

verify that each end flap on a cardboard carton is glued down.

Sensors: Presence PLUS P4 EDGE, with

LCF08 lens, LEDRB85X220M

red backlight, fixed-field photoelectric used as a trigger.

Operation: After a cardboard carton is packed, the flaps on

both ends are glued down. The

Presence PLUS P4

EDGE’s Locate tool

finds the edge of the box, then the Edge tools checks whether the

upper and lower horizontal edges are the same distance from the

centre of the box. If not, the flap is not glued, and the box fails

the inspection. |

Part Presence/Absence & Orientation

Objective: To

verify that the cap of a washer reservoir is present and oriented

within an accepted range of rotation.

Sensors: Presence PLUS P4 GEO with

LCF16 lens,

LEDRR62X62 red

ring light, Verification Touch Button (VTB) used as a trigger.

Operation: An operator places a capped reservoir on the

inspection stand. The Presence PLUS P4 GEO’s Geometric Count tool

verifies that the cap is on the reservoir, that the logo is printed

on the label, and that the cap is not rotated beyond the accepted

range. |

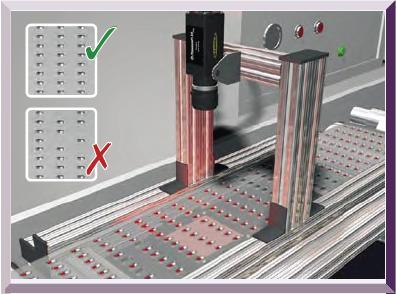

Component Inspection

Objective: To

verify that all weld nuts in an automobile door component are

present, oriented with the right side up and in the correct

location.

Sensors: Presence PLUS P4 GEO 1.3 with

LCF16LMP lens,

HFFW24AC tubular fluorescent light, PLC used as a trigger.

Operation: Nuts are welded to a component of an automobile

car door. The Presence PLUS P4 GEO uses four Geometric Count tools

check whether the weld nuts are correctly oriented and aligned over

the bolt holes. |

Blister Package Verification

Objective:

To verify that the blister packet is

filled with a complete tablet of medication in each cell and that

the blister is free of debris.

Sensors:

Presence

PLUS

Pro vision sensor,

LEDRB85X220W red diffused backlight, PLC used as a trigger.

Operation:

A blister machine fills each cell on

a web of blister packets with a tablet. Before the packets are

sealed and cut, the

Presence

PLUS

Pro uses the Blob

tool function to inspect each row to verify each cell has a complete

tablet inside and also ensures no broken tablets or other debris are

incorrectly packaged. If a missing or partial tablet is found, the

blister is rejected. |

Label Positioning

Objective:

To verify correct label placement on

bottles of tablets.

Sensors:

Presence

PLUS

Pro vision sensor, with

LCF16 lens,

LEDRR80X80W red ring light, photoelectric sensor used as

a trigger.

Operation:

As bottles of

tablets pass on a conveyor, the

Presence

PLUS

Pro

verifies that the label is present and positioned correctly. The

Edge and Measure tools measure the distance between the top of the

label and the top of the bottle to check height. The distance

between the side of the label and the side of the bottle is also

measured to make sure the label is centred on the face of the

bottle. |

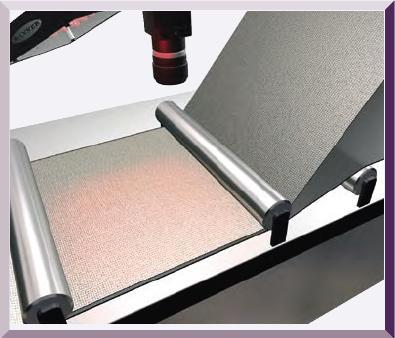

Assembly Verification

Objective:

To verify that cloth belting has been

added to a band of tyre rubber

Sensors:

Presence

PLUS

Pro vision sensor, with

LCF25R lens,

LEDRA80X80W red area light, PLC used as a trigger.

Operation:

On a web, cloth belting is bonded to

one side of a band of hot rubber. Using the Average Grey Scale tool,

the

Presence

PLUS

Pro detects the difference between

the brightness of the cloth and the darkness of the rubber to make

sure the cloth has been applied to the rubber. |

Part Orientation Verification

Objective:

To verify that a ring is placed correctly on a component of an

assembled part.

Sensors:

Presence

PLUS

Pro

vision sensor, with LCF08 lens,

LEDRR80X80W red ring light, PLC used

as a trigger.

Operation:

An assembler places the ring over the part. The ring fits in two

possible positions, but only one position is correct. The

Presence

PLUS

Pro

uses the Edge tool to check that the gasket is in the correct

position, within an accepted variation of rotation. |

Component Moulding Inspection

Objective:

To inspect moulded plastic steering

wheel components for excess or deficient material.

Sensors:

Presence

PLUS P4 OMNI 1.3, with

LCF08LT

lens and LEDRA80X80M red area light.

Operation:

After a steering wheel component is

removed from the mould, the

P4 OMNI 1.3 inspects it for areas

that received too much or too little material during the moulding

process. Defective components are diverted from the line. |

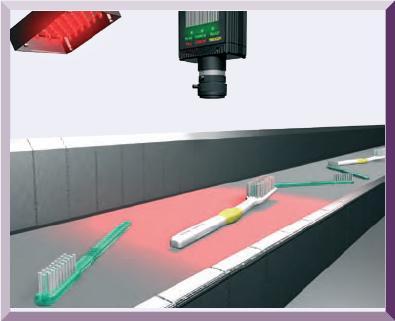

Toothbrush Sorting

Objective:

To sort different styles of

toothbrushes before they are packaged.

Sensors:

Presence

PLUS P4 OMNI, with

LCF08LT

lens and LEDRA80X80M red area light.

Operation:

As toothbrushes pass on a conveyor,

the P4

OMNI detects shape differences, regardless of their

orientation on the conveyor. The different styles are automatically

separated at the end of the line, before they are packaged.

|

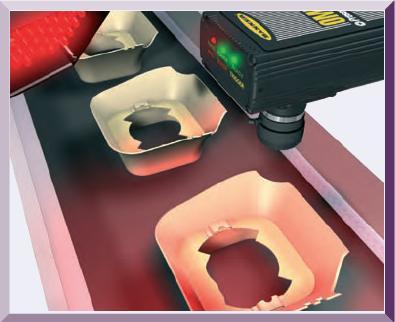

Food Packing Inspection

Objective:

To inspect

boxes of chocolates for missing or damaged pieces to make sure each

nest contains a candy and that the candies are not damaged.

Sensors:

Presence

PLUS P4 OMNI with

LEDR80x80M light and

LCF16LMP lens.

Operation:

After boxes of

chocolates are filled, the

P4

OMNI checks

whether the box contains the correct number of pieces. It also

checks that the shapes of the candies are within tolerance, to

verify that none are damaged.

|

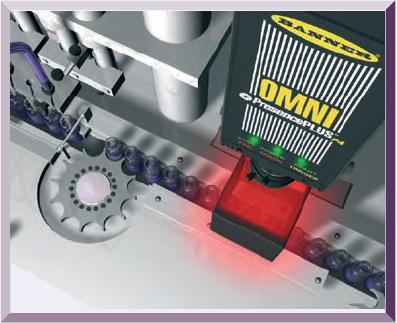

Glass Vial Integrity Check

Objective:

To check for damaged lips on glass

vials on a high-speed filling line.

Sensors:

Presence

PLUS P4 OMNI with LEDRO50N

light and LCF50LMP lens.

Operation:

Glass vials can be damaged during filling

and transfer. The P4

OMNI inspects the opening, or lip, of

each vial as it passes on a high-speed conveyor to detect vials with

chipped or cracked lips. If it detects any damage, it diverts the

vial from the line before it is sealed and capped. |

|