|

| |

|

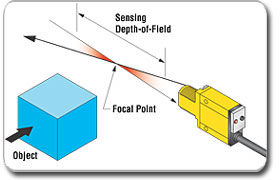

Convergent Mode Sensing |

|

How It Works

Convergent-mode

sensors use reflective energy very efficiently, unlike divergent-mode

sensors. Convergent-mode sensors use a lens system to focus emitter and

the receiver elements to an exact point in front of the sensor. Like

diffuse-mode and divergent-mode sensors, convergent-mode sensors detect

an object when that object completes or

"makes"

the light beam. This design produces a small, intense, and well-defined

sensing area, at a fixed distance from the sensor lens. It is a very

efficient use of reflective energy.

|

|

|

Pros: High Excess Gain

Convergent-mode

sensors make the most efficient use of reflective sensing energy. This

is a good mode to use to detect objects with low or high reflectivity,

when you canít use an opposed or retroreflective mode sensor. However,

the small beam of the convergent-mode sensor can be easily deflected by

highly specular or shiny surfaces.

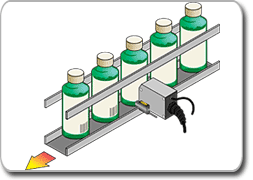

Pros: Counting Radiused Objects

Convergent-mode

sensors allow the sensing light energy to be focused on the nearest

point (i.e. the tangent point) of a radiused object. For this reason, it

is a good choice for counting bottles, jars, or cans, where there is no

space between adjacent products.

Pros: Accurate Positioning

Convergent-mode

sensors have well-defined effective beams, especially at the focal

point. Therefore it is a good sensing choice, after opposed mode, for

accurately detecting the position of edges. However, convergent-mode

sensing becomes a first choice for accurate position sensing of clear

materials.

Pros: Fill Level Applications

Convergent-mode

sensors may be used in some applications for detecting the fill level of

materials in an open container, where an ultrasonic sensor would not

work.

Pros: Colour Sensing

Convergent-mode

sensors are available with a wide variety of LED colors such as blue,

green, and red. These sensors work well in colour registration

applications.

|

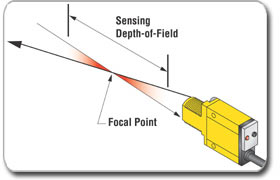

Cons: Depth of

Field

Convergent-mode

sensors require that the surface to be detected pass at (or close to)

the focal point from the sensor lens.

Avoid the use of

convergent-mode sensors for detection of objects that pass at an

unpredictable distance from the sensor.

Cons: Effect

of Surface Reflectivity

As with any

photoelectric proximity mode, consider the reflectivity of the surface

to be detected. The distance within which a convergent-mode sensor will

detect an object is relative to that objectís optical reflectivity.

If a shiny background object returns unwanted light, tilt or rotate the

sensor to move the sensing beam so that it is not perpendicular to the

shiny surface.

|

Application -

Ink Jet Printing Registration

Objective:

To sense

the leading edge of bottles and provide the trigger signal to an ink jet

printer.

Bottles are channeled through guide

rails to control the distance to both the sensor and the ink jet

printer. The convergent-mode sensor consistently triggers the printer at

the same point on the circumference of each bottle to provide accurate

printing registration.

|

|

Review

The convergent mode makes

very efficient use of reflective energy. It uses a lens to focus its

beam to an exact point, which produces a small, intense and well-defined

sensing area at a fixed distance in front on the sensor. Convergent-mode

sensors are excellent in applications involving accurate positioning,

counting radiused objects, and colour sensing.

Reconsider the use of convergent sensors when the object to be detected

passes by at unpredictable distances, or if the object is very shiny.

|

|