|

| |

|

Retroreflective Mode Sensing |

|

How it Works:

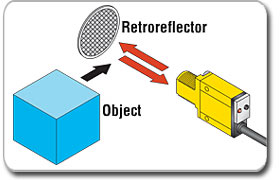

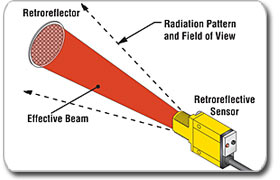

Unlike an opposed-mode sensor, a retroreflective sensor contains

both the emitter and receiver elements. The effective beam is

established between the emitter, the reflector, and the receiver.

As with an opposed-mode sensor, an object is sensed when it

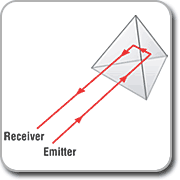

interrupts or "breaks" the effective beam. Most reflectors are made

up of many small corner-cube prisms. A light beam enters a corner

cube prism through its hypotenuse face and is reflected from the

three surfaces. In this way, the reflector returns the light beam to

its source. Most corner-cube reflectors resemble bicycle

reflectors, and are molded using clear acrylic plastic, manufactured

in various sizes, shapes, and colours. If an opposed-mode sensor is

not an option, then a retroreflective-mode sensor may be a good

second choice. Retroreflective mode sensors offer relatively long

ranges.

Reliable sensing

Retroreflective sensing is a beam-break mode. So, it is

generally not dependant upon the reflectivity of the object to be

detected. For this reason, the retroreflective mode is a relatively

reliable sensing mode.

|

Reflector Prisms |

|

Pros: Convenience

A

retroreflective-mode sensor offers a convenient alternative to

opposed mode when sensing is possible only from one side, or if

electrical connections are only possible on one side.

Convenient Connections

-At one end only

Minimising "Proxing" |

Cons: Less Excess Gain

Retroreflective-mode sensors lose excess gain twice as fast as

opposed-mode sensors, due to dirt build-up on both the reflector and

the sensor lenses. This is because the light travels through four

lenses, once from the emitter to the reflector and back from the

reflector to the receiver. There is also much less available excess

gain in a retroreflective mode sensing beam, due to the

inefficiencies of the reflector and because the light must travel

twice as far to reach the receiver, as compared to the opposed mode.

Cons:

Effective Beam

It's

difficult to create a small effective beam with a retroreflective

mode sensor, so avoid using this mode for detecting small objects or

for precise positioning control. We can offer some retroreflective

sensors that have an effective beam of less than 25mm.

Effective Beam

Cons:

Clear Materials

In the

retroreflective mode, an object must interrupt the beam to be

detected. As with opposed mode, it is not recommended that you use a

retroreflective mode sensor to detect transparent or translucent

objects.

However there are several sensors designed specifically as clear

object detectors in low excess gain environments.

Clear Objects

Cons:

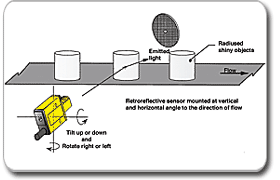

Shiny Materials

The optics of a good

quality retroreflective sensor are designed and assembled with great

care to minimize "proxing" (undesirable reflection of the

sensing beam directly back from an object that is supposed to break

the beam). However, an object

with a shiny surface that presents itself perfectly parallel to a

retroreflective sensor may return enough light to cause that object

to pass by the sensor, undetected. This problem can be compensated

for by angling the sensor relative to the object to avoid direct

reflection or by using an anti-glare or polarizing filter.

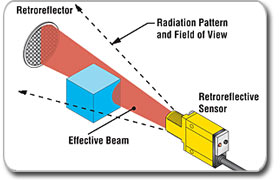

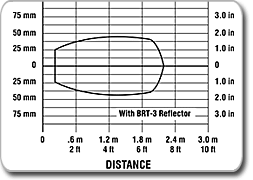

Cons: Reflector Size

and Type

Except at close range, the size of the reflector becomes important.

The width of the beam pattern for each retroreflective sensor serves

as an estimate of how much reflector area should be used to return

the maximum amount of light. Reflector size does affect the range.

The smaller the target size, the smaller the effective beam, and the

shorter the range.

Also the efficiency of different reflector material types varies

Reflector Size

Cons:

Blind Spot at Close Range

Most

retroreflective sensors are designed for long-range sensing, and

suffer a "blind spot" at close range. A

"Blind Spot" is an area close to a sensor lens, where light energy

is returned to the emitter rather than the receiver, rendering the

sensor effectively blind. This effect is most pronounced with some

retroreflective sensors.

Check the excess

gain curve of your retroreflective mode sensor to see where the

"blind spot" occurs.

Blind Spot

|

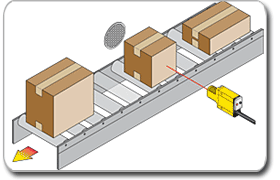

Application - Cardboard

Box Detection

Objective:

To reliably

count boxes moving on a high-speed conveyor line.

The retroreflective optics of a MINI-BEAM sensor are excellent for

reliably sensing boxes on a conveyor belt. This sensor generates one

solid count from each box moving through the beam.

|

|

|

Review

A retroreflective

sensor contains both the emitter and receiver element. The

effective beam is established when the emitter sends a light beam

which is bounced off a retroreflector, back to the emitter. An

object is detected when it breaks this effective beam.

Retroreflective-mode sensors offer reliability, and are convenient

in applications where sensors can be mounted only on one side of a

process. However, retroreflective sensors can lose gain twice as

fast as opposed mode sensors, and they aren't always the best choice

for sensing shiny, clear, or very small objects.

NEXT |

|