How It

Works

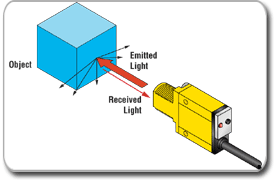

In diffuse-mode sensing, light emitted from the sensor strikes the

surface of the object to be detected and is diffused back, i.e.

sending some light back to the

receiver,

which is usually housed with the

emitter.

With a diffuse-mode sensor, the object is detected when it "makes"

the beam, that is, the object reflects the sensorís transmitted

light energy back to the sensor.

Most

diffuse-mode sensors use

lenses

to

collimate

(convert a

divergent beam into a parallel beam)

the emitted light rays to gather in more light. These lenses also

help to extend the

range

of diffuse-mode sensors. |

Diffuse Sensing

Collimating Lens |

Pros:

Convenience

Diffuse-mode sensors have only one item to be mounted: the sensor

itself. This is ideal for situations where a sensor can be mounted

only on one side.

Pros:

Conveyors

A diffuse mode sensor may be used if an

opposed

or

retroreflective-mode sensor isn't practical in a

straightforward product presence sensing application. The

sensor-to-object distance should be from a few centimeters to a

meter.

Simple Close Mounting

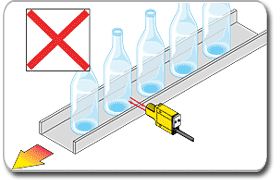

Inaccurate for Glass

|

Cons: Dependant on Object

Reflectivity and Shape

The response of a diffuse-mode sensor is dramatically influenced by

the surface

reflectivity

of the object to be sensed. The reflectivity of an object directly

affects the distance at which it can be reliably sensed by a

diffuse-mode sensor. The shape of the object to be sensed is as

significant as reflectivity. Radiused or rounded objects present the

sensor with less surface area and therefore have a smaller signal

return path.

Cons: Shiny Surfaces

The use of

collimating

lenses maximizes sensing ranges of diffuse mode sensors. However, if

you are using diffuse sensors to detect shiny objects, the

collimating lens will affect the sensing angle. The sensor needs to

be perfectly parallel to the object being sensed in order to

guarantee a return light signal.

Cons:

Background Objects

As a general rule, verify that the distance from diffuse mode

sensors to the nearest background object is at least four times the

distance from the sensor to the object to be detected. However, if

the background is more reflective than the object to be detected,

more clearance will be required. If the background is not

controllable, consider the use of a

background

suppression sensor (similar

to a diffuse sensor, but with a defined range limit e.g. fixed-field

and adjustable-field).

Cons:

Small Parts Detection

Diffuse sensors have less sensing

range

when used to sense objects with small reflective area than when used

to sense objects with a large reflective area. Also the lens of most

diffuse mode sensors creates a

"blind spot"

for small parts that pass close to the lens.

A "Blind Spot" is an

area close to a sensor lens, where light energy is returned to the

emitter rather than the receiver, rendering the sensor effectively

blind. This effect is most pronounced with some retroreflective

sensors.

Cons: Low Excess Gain

Most diffuse mode sensors

lose their

gain

very rapidly as dirt and moisture accumulates on their

lenses.

In some instances, dirt build-up on the sensor lens can channel the

light beam from the

emitter

directly to the

receiver,

so that the sensor will act as if an object is constantly in front

of it. This event is called optical crosstalk.

Cons: Count Inaccuracy

Diffuse mode sensors are

usually a poor choice for applications that require accurate

counting of radiused parts. Diffuse sensors are particularly

unreliable for counting glass or shiny objects, small parts, objects

with irregular surfaces, or parts that will pass by the sensor at

varying distances.

|