|

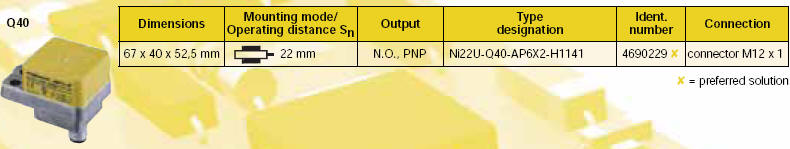

Uprox+ Sensor Q40

integrated into a stamping press

The height adjustment feature of the Q40

is used to align the switch thus saving additional steps, such as

an adjustment of the mounting surface. Also the switch-point can be

easily adjusted to the optimum target position. The operating distance

is easily and precisely set also in the recessed mounting mode using a

countersunk screw without having to remove the switch. All these factors

contribute to cost savings compared to conventional solutions: less

proximity switches are needed, material machining is superfluous and

mounting procedures are simplified. Highly visible LEDs ensure reliable

function and adjustment control in all mounting modes. When replacing a

defective proximity switch, the original setting of the operating

distance is retained. |

|

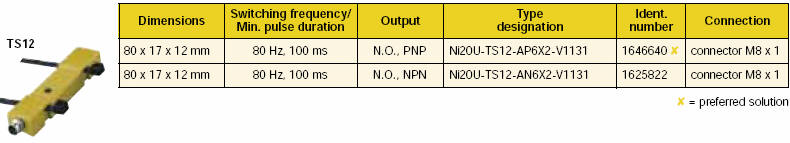

Uprox+ Sensor

TS12 replaces a range of ring sensors

The small parts feeding procedure in

assembly and handling applications must be monitored e.g. that the

screwing robot is loaded exactly with one screw. If no screw is fed, the

work piece may be damaged or not properly assembled. If two screws are

fed, then the screw robot may be damaged. This application was solved

previously with ring sensors, but these are difficult to mount and

different ring sensors are needed for every tube diameter.

Due to the new Uprox+ printed coil technology, it is now possible to

detect tube-guided small parts reliably from the side. The tube sensor

TS12 is a replacement for the large variety of ring sensors. Only a

single sensor is needed to solve all applications involving various tube

diameters. The simple retaining strap saves additional brackets and the

sensor can be mounted after final installation of the feeding

tube. |